Today’s blog post, “How Laser Scanning can be used in Construction Today,” is written by Ken Robbins, of Robbins3D.

What is Laser Scanning?

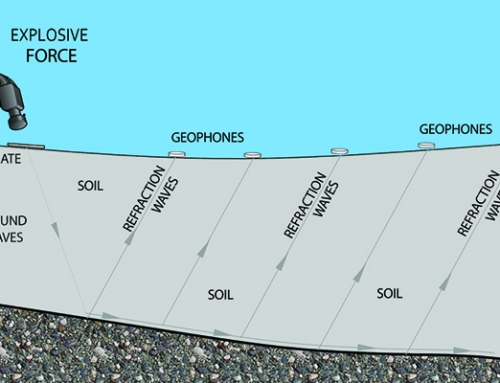

Simply put, the scanner emits a laser beam at just under 1 million times per second. The beam bounces back from the surface of the subject area to create a point in space with an X, Y and Z coordinate value. Millions of points are collected to form what is commonly referred to as a “point cloud”. The points collected are so dense that they create what appears to be a 3 dimensional picture of the area. A picture so detailed, it could be mistaken for a photograph. Multiple scanning locations can be oriented together, merging the multiple point clouds into one project point cloud. The individual clouds or the single project cloud can then be utilized to create 2 dimensional and 3 dimensional models.

A Robbins3D Project Example

Exterior facade scanning.

The project involved a multistory building addition adjacent to an existing structure. The goal was to provide the structural steel fabricator with dimensions for beams to be shop fabricated off-site. An expansion joint if no more than 2 inches in width between the beam end and the existing structure was required.

The existing structure face was known to be out of plumb, therefore dimensions were needed at every beam location and at all floor elevations.

Targets were located on the existing structure and those targets were tied into the existing project coordinate system. This would allow the post processing software to orient the scans of the existing structure with the design model. The existing exterior was then scanned to obtain the point data needed for modeling the beam sizes.

Once scanned and oriented into the design model, the floor elevations were “sliced” at each section and dimensions were obtained from the proposed adjacent column line to the existing face. The 2 inch expansion joint size was then subtracted, resulting in the desired beam length. The scan data resulted in dimensions meeting the tolerance within 2.0 mm. The fabrication company created the beams in their shop environment. The beams were delivered to the job site and lifted into place. Once installed all of the beams met the design criteria.

The scans inserted in AutoCad. The proposed column lines are in red. The column line ending in an existing window is highlighted.

The Benefits Of Laser Scanning

The first benefit to the project was accurate exterior dimensions

obtained and tied to the design coordinate system. This resulted in

an overall time savings and kept the survey team safely at ground

level, all while obtaining point data all the way to the roof line.

The second benefit was quickly and accurately modeling the site and obtaining the required dimensions prior to fabrication and erection of the perimeter steel. A design flaw was also discovered that would have resulted in a new beam terminating in an existing window opening. Plan adjustments were made to correct this issue. This eliminated site safety and project timing issues. The steel erection continued without a hitch and the project was on time and under budget.

On our next Guest Blog.

Our second example will focus on an interior project, its scope and the benefits of laser scanning.

About Robbins3D.

Robbins Land Surveying, Inc. was founded in 1999 by Ken and Nicole Robbins. Ken’s extensive background in surveying and implementation of new techniques and new technologies has helped Robbins3D to become a leader in the field. Nicole’s background in finance and efficiency keeps Robbins3D moving forward and remaining an industry leader. In 2013 Robbins3D became a natural extension of Robbins Land Surveying, Inc. In a constantly changing 3 dimensional measurement world, Robbins Land Surveying, Inc. implemented 3D Laser Scanning into our regular production work-flow.

Robbins3D services run the full spectrum of land surveying ,measurement and 3D cad modeling. Utilizing robotic total stations, RTK satellite systems, 3D laser scanning and now aerial drone technology for mapping and construction documentation, Robbins3D can handle and deliver any surveying and measurement needs.